The Benefits of Asphalt Crack Repair

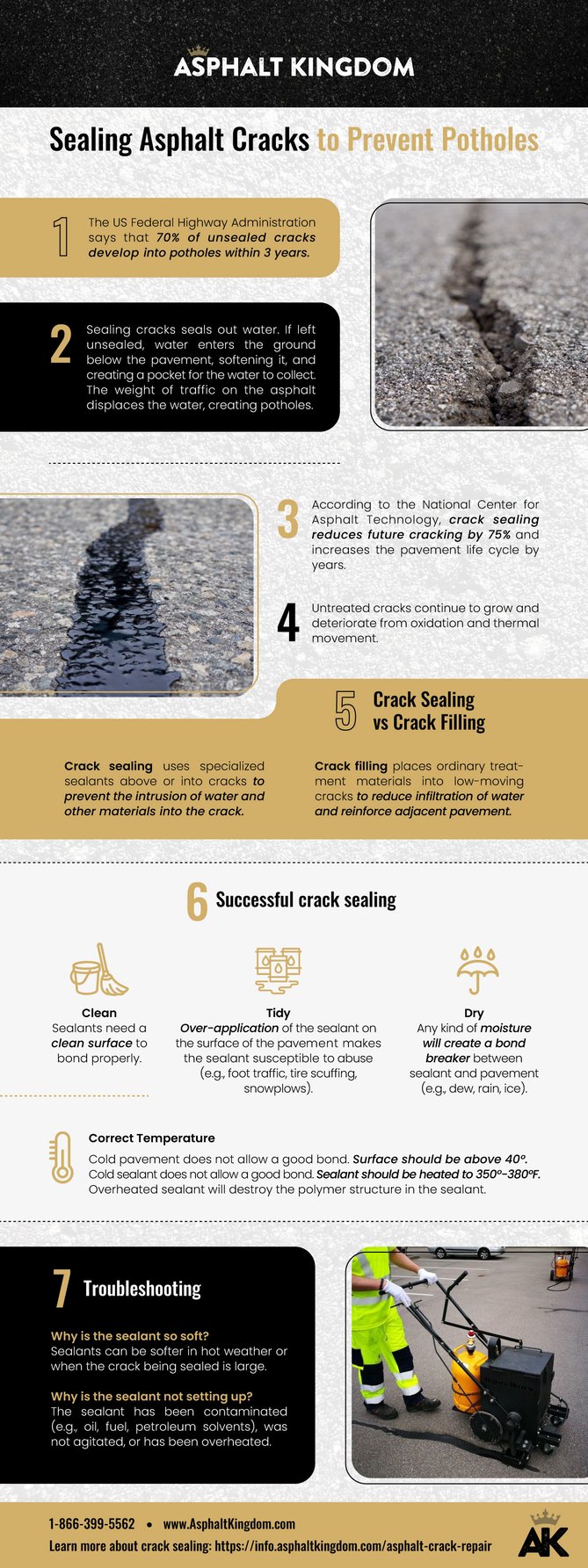

Water is one of the worst things that can happen to a cracked asphalt surface. Once water trickles into seams and voids, it can erode the foundation or freeze, then expand and break things apart. In colder regions, one season without proper asphalt crack filling can turn minor lines into major potholes.

Cracks also collect dirt, sand, and organic debris. Weeds start growing and push the pavement apart even more. Fixing and sealing driveway cracks before they become potholes is the smartest thing you can do. A small investment in asphalt crack sealing and patching now can extend the life of your pavement and save you from having to pay for a full replacement later. When you combine asphalt crack filling with asphalt crack sealing, you block water before it reaches the base.

When Is The Best Time To Fix Cracks?

Do you have a section of pavement that is starting to spider and split? If you do, you are not alone. Asphalt deterioration often shows up after stretches of icy or snowy weather.

Thawing cycles cause blacktop to crack, crumble, and decay, especially if the surface is not protected with a fresh coat of sealer every few years. Once moisture gets into unprotected cracks, damage speeds up

The key to long term pavement health is to tackle asphalt crack filling as soon as you see lines forming. Putting off repair work leads to more damage and eventually forces you into costlier asphalt replacement.

Why Do Asphalt Cracks Form?

Cracks can be caused by a weak or poorly compacted base, by not having a thick enough layer of asphalt, or by a lift that is too thick to compact correctly. When asphalt is first installed, the mix may not be blended well or may not match the climate.

Extremely heavy vehicles, tree roots, and drainage problems are all common reasons for cracks. Asphalt also expands and contracts during the freeze thaw cycle. That movement slowly pulls the surface apart.

This is why you want a simple, repeatable asphalt crack filling program every year. Cleaning cracks, completing asphalt crack sealing, and keeping water out of the base will stop weeds from taking over and keep your parking lot or driveway safer to drive and walk on.

Preparing for Crack Filling

Surface prep is the most time consuming part of the job, yet it is also where long lasting repairs are won or lost. Any debris or weeds that are left in the crack will weaken your asphalt crack filling work. For the strongest repair, the crack sealer needs a clean and solid area to bond to. Good prep also helps asphalt crack sealing adhere better and last longer.

Surface prep is the most time consuming part of the job, yet it is also where long lasting repairs are won or lost. Any debris or weeds that are left in the crack will weaken your asphalt crack filling work. For the strongest repair, the crack sealer needs a clean and solid area to bond to. Good prep also helps asphalt crack sealing adhere better and last longer.

A pro will often use specialized asphalt crack filler machine like a heat lance to blast out dust and dry the walls of the crack. If you are a homeowner, you can still get the job done with simple hand tools you probably already own.

You do not need to pressure wash the asphalt before you start crack repair. Pressure washing forces water deep into the crack, which slows drying and makes it harder for hot rubber or other crack seal products to bond.

Always check the weather before you start. Ideally, you want several dry days in a row and temperatures over 60 degrees Fahrenheit. Those conditions let your crack fill cure properly and keep the damage from spreading.

Clean the Surface Prior to Asphalt Crack Filling

If weeds or grass are growing in the cracks, pull them out as deep as you can. When roots will not budge, you can use a bit of vinegar to kill them off.

Use a chisel or screwdriver to scrape loose rocks, debris, and leftover vegetation from the cracks. Follow that with a wire brush or hard bristle broom so dust is swept away.

If you want to speed up this stage, use a walk behind gas blower or a backpack blower. Contractors often rely on a dedicated crack cleaning machine that routes out the crack and leaves it ready for asphalt crack sealing in one pass. A clean, dry crack is the key to asphalt crack sealing that holds through freeze thaw cycles.

Make Sure the Surface is Dry

The success of any crack repair job depends on having a dry, solid area for material to stick to. That is why you should avoid pressure washing right before asphalt crack filling. Water takes a long time to evaporate from deep in the crack.

If you do choose to wash the surface, dry the area with an air compressor. For tiny cracks, you can even use a hair dryer to push remaining moisture out.

Determine the Size of the Cracks

As you clean, take a moment to note how wide and deep each crack is. For simple planning, divide your damage into three groups: shallow cracks, deeper ruptures, and alligator cracks.

Each type needs a different strategy. While you inspect, keep an eye out for surface spidering that looks like dry, brittle skin. That visual is a strong sign that your surface is due for a sealcoat once you finish asphalt crack filling and patching.

- Shallow cracks are about a half inch deep or less. When you check your asphalt regularly and you have only just noticed a few lines, the depth is usually shallow.

- Deep cracks are more than a half inch deep. Fill deep cracks with sand until they are about a half inch from the surface before you start placing crack sealer.

- Alligator cracks are clusters of small, connected cracks that resemble the scales on an alligator's back.

DIY Crack Repair

Filling Cracks Less Than 1/2" Wide

Filling small cracks is straightforward work that most homeowners can tackle in a weekend. Cold pour crack filler is easy to apply and ideal for residential projects where you only have light traffic.

You can use a caulking gun as your asphalt crack repair tool or simply pour a little crack fill directly into the line. Then pull a u-shaped squeegee across the surface to push material down into the void. The goal is to complete asphalt crack filling in a single smooth pass that leaves the line slightly crowned so it can settle.

Cold pour filler is not recommended for wide or very deep cracks. On larger openings, it can sink down into the void or even pour right through to the base layer, so the top never looks full even though the crack is technically sealed.

Filling Cracks More Than A Half Inch Wide

Repairing larger cracks is slightly more involved because it calls for rubberized hot pour crack filler. If you are a homeowner, you can hire a contractor or invest in the right tools so you can do the work yourself.

Pros melt crack rubber in a dedicated asphalt crack repair machine that keeps material at the right temperature for easy placement. Once the filler is melted, move steadily along the joint and fill all crevices and corners.

Slightly overfill the crack and then tamp it with an oiled piece of plywood or a steel roller. Once cooled, the material will sit level with the surrounding pavement and give you a clean finish that is ready for asphalt crack sealing and sealcoating.

Note: Hot pour works best for cracks that are two inches wide or less. Anything wider is considered a pothole that needs an asphalt patch rather than simple asphalt crack filling.

DIY Alligator Crack Repair

Alligator cracks look intimidating, yet they are fairly easy to repair with Gator Patch and a squeegee. You will need the temperature to be at least 50 degrees Fahrenheit so the patch can cure correctly, so always check the forecast before you start.

To repair, pour out a bit of Gator Patch and spread it into a thin, even layer with your squeegee while filling the cracks from different angles. Let the first lift dry and then apply a second thin coat. Once cured, follow up with sealcoating so your asphalt crack filling and patching are protected beneath a uniform black surface.

Learn To Patch Asphalt In A Few Easy Steps

Patching potholes on your driveway or small lot is a simple project. Modern patching products make it easy for homeowners who are not into regular DIY work to complete small repairs.

One of the most popular options is Cold Asphalt Patch, a cold pothole filler that simplifies repair into three basic steps.

The first step is to remove loose soil, debris, or broken asphalt from the pothole. If the edges are crumbling, square them up with a chisel until you have solid pavement around the hole.

Cleaning well gives your patch a solid surface to bond to so it will last. Sloppy prep here will undo good asphalt crack filling and crack sealing work later.

Next, pour Asphalt Patch into the hole and compact it with a tamping post or shovel. Pack material tightly to remove air pockets, then add more patch until you have a small mound above the surrounding surface.

The third step is to do a final tamp. You can use a hand tamp, a plate compactor, or even your vehicle. Drive back and forth across the mound until it is level with the pavement.

Despite how simple this looks, the results are impressive. Cold patch is basically hot asphalt that has been treated so it stays workable at ambient temperatures. Once compacted in place, it locks into the existing pavement, bridges your asphalt crack filling work, and delivers a durable repair.

The Benefits of Using Cold Asphalt Patch

Cold asphalt patch simplifies pothole repair and keeps you away from burners and very hot material. You do not have to buy a melter or handle heavy kettles of hot asphalt.

For many homeowners, investing in an AK10 asphalt crack filling machine is not practical because it will sit idle for most of the year. Cold patch lets you fix potholes as they appear, and you can combine it with basic asphalt crack filling and spot sealcoating to keep the surface in good shape.

Cold patch is safer because you are not exposed to extreme heat or heavy fumes. You can also work in slightly damp conditions, since cold patch products tolerate a bit of moisture in the pothole.

Traditional hot asphalt requires a completely dry base and often forces you to close the surface to traffic for several hours. In contrast, cold patch sets quickly. Many products are ready for light traffic in a few hours, which keeps driveways and access lanes open.

Pro Tip For Contractors: When you have a high ridge on your hot crack fill, use your torch to blend the edges for a smoother look. Use a low flame and take your time so you do not burn the material.

Use coarse sand to pre fill deep cracks so the crack fill will top off in a single pass. If you skip that step, you will need to go over wide cracks many times before they fill correctly.When you price your jobs, break out the crack fill and make it a clear line item. That way the sealing price is in line with competitors who may not include asphalt crack filling in their quotes. It also protects you from clients who assume crack repair is already included.

Submitted by Todd Phillips

Check out how simple it is to seal cracks with the RY10 PRO and hot pour crack sealer:

Learn More: Enroll In Our Free Course

Pavement Asset Management Course

Register Now

This free asphalt driveways course is everything a property owner needs to know about asphalt maintenance and repair.

To go deeper on pavement care, enroll in our free Pavement Asset Management Course. This asphalt driveways course walks property owners through asphalt crack filling, asphalt crack sealing, sealcoating, and long term maintenance planning so you can protect every surface on your site.

You can study at your own pace and revisit key asphalt crack filling lessons any time. We respect your privacy, and you can review our Privacy Policy before you register.

Tips for Pros

Top with Sand

Top repaired lines with sand. You can broadcast sand by hand or use a sand dispenser.

Sand makes crack filler safe to walk on earlier than if you leave rubber exposed. On hot summer days, sand keeps the crack fill from staying sticky.

Sand on top of your repair also adds durability. It creates a toothy surface that bonds well with sealcoating or asphalt sealer, so the crack filler does not repel the finish coat.

Let the Area Cure Properly

Once asphalt crack filling is complete, let material cure for 24 to 48 hours before you open the area to traffic.

If you have potholes, repair them during the same visit. It is easier to fix them now than to return later. We are pleased to offer Cold Asphalt Patch, a rapid setting cold patch that works in any season and only needs three steps from start to finish.

After repairs are done and cured, seal the asphalt to lock your crack repair under a protective layer.

Wondering what steps you need to take to do asphalt driveway repair yourself? It is easier than you might think. Follow our quick guide at the link below and you will be ready to seal up your driveway before temperatures start to drop.

Read the Asphalt Driveway Repair Guide

Sealcoating and Parking Lot Striping

Timing

If you are working on a property that requires line striping, remember that sealcoating will cover existing lines. Wait at least 12 to 24 hours for water based paint and 48 to 72 hours for oil based paint before painting the parking lot lines.

There is a wide timing window because sunlight, humidity, and temperature all affect how fast treatments cure. Be patient and check the surface instead of rushing. That habit will protect your asphalt crack filling and help every coat you place last longer. Make sure asphalt crack sealing is fully cured before you apply sealer or paint.

With care and timing, you will know when to start pavement sealcoating after crack and pothole repair, and how long to wait before you begin parking lot striping.

Sealcoating

Sealcoating should be applied every two to three years. For best results, use professional grade sealer that rejuvenates and protects the surface.

Asphalt Kingdom’s asphalt emulsion sealer is perfect for weekend do it yourself work because it dries fast and is simple to use.

A five gallon drum of our sealer will cover up to 300 square feet of asphalt. You can apply it with a brush, squeegee, or one of our spray systems.

Larger quantities, such as a 55 gallon drum or 275 gallon tote, are better suited to parking lots, airports, and other large paved areas. Our supply calculator will tell you exactly how much product you need for any job.

Line Striping

If you have a parking lot with a sealed surface, you need clear, visible parking lines. After crack repair and sealcoating, existing markings will be hidden under fresh black sealer.

Refresh your lines with new paint. A small lot can be handled with a small line striper that uses aerosol cans, while larger parking lots can benefit from a Titan PowrLiner or a Newstripe Line Striping Machine.

Our free property owner course teaches you everything you need to know about maintaining parking lots, from basic asphalt crack filling and asphalt crack sealing to sealcoating and layout.

Add Asphalt Crack Repair to Your Business

Whether you run a professional sealcoat company, manage properties, or own a landscaping business, you can profit by adding a new service to your business.

Whether you run a professional sealcoat company, manage properties, or own a landscaping business, you can profit by adding a new service to your business.

Having both a portable crack filling machine and sealcoating equipment under one roof means less hassle for your customers. They prefer to work with one vendor who can handle asphalt crack filling, asphalt crack sealing, and sealing in a single visit.

In the long term, that saves them time and money, and it positions your business as the easy choice when they need more work done.

Shop Related Products

Walk Behind Leaf Blower

Sidewalk Edger

Crack Seal Melter & Applicator

Advice That You Can Trust

Asphalt Kingdom is not new to asphalt crack repair.

We have worked with thousands of clients, including international airports, school districts, hotels, restaurants, contractors, and many more who needed help with crack repair programs. We have seen almost every pavement problem and can help you build a simple asphalt crack filling plan that fits your site and your budget.

You are in the right place if you want practical advice on asphalt crack repair. Whether you need crack repair equipment or asphalt crackfiller, our team will guide you so you get your job done correctly and on budget.

Remember to take advantage of our free online courses on Home Asphalt Repair and Commercial Property Asphalt Repair. You can always call us at 1-866-399-5562 for free expert advice on asphalt crack filling, asphalt crack sealing, sealcoating, and more.

Quick Recap: Crack Filling and Crack Sealing

In the field, people often use the words crack filling and asphalt crack sealing interchangeably. When you hear someone talk about crack sealing, they usually mean keeping water and debris out of cracks with hot rubber or similar material. The main points to remember:

- Plan crack sealing early so water never reaches the base.

- Match the method to the size of the crack and traffic level.

- Combine crack sealing with regular sealcoating for the best surface protection.

- Build a simple annual checklist so crews work the same way every time.

- Take photos before and after the repair so you can track how well your maintenance plan performs.