Asphalt Services to Offer in 2026 (What Customers Need)

Stop small pavement problems from turning into big callbacks. See the asphalt services that matter ...

Save money by saving your paving investment. Asphalt patching is the most cost-effective way to protect and repair your asphalt surface and foundation. By repairing potholes, you get an instant improvement in look and safety while protecting against further damage and erosion to your pavement.

You save a bucket-load of money by repairing over repaving, both short-term and long-term.

Potholes can develop in any weather, buy they seem to happen more frequently during the winter months after a period of snow or ice. They can show up quickly and often seem to spread across an otherwise smooth driveway.

That's why it's essential to have the right materials on hand for fast asphalt repairs. The best product for pothole repair is cold mix asphalt that contains a polymer adhesive that allows for permanent repairs.

Unlike hot mix asphalt, which is used only by professional contractors, asphalt cold patch is easy to use and can be applied under any weather condition. The material cures as it's exposed to air and hardens quickly.

The ideal thickness of asphalt repairs should be approximately two inches. If potholes are deeper, they should be filled first with angular crushed gravel and then patched with the cold mix asphalt.

If untreated, asphalt cracks can lead to potholes. That's why it's also important to have an excellent commercial quality asphalt crack filler on hand, along with asphalt cold patch.

The product is easy to use and dries in less than an hour. It's as simple as pouring filler directly into a crack and smoothing it with a squeegee.

Like potholes, driveway cracks can escalate the erosion of your asphalt in addition to being potential tripping hazards.

Water can penetrate into the asphalt through small cracks that aren't filled. When this water freezes, it expands, creating even larger cracks, as well as potholes and chuckholes.

Asphalt crack filler along with asphalt cold patch is the best way to repair your asphalt and stop the cycle of decay and deterioration.

Generally speaking, a cold asphalt filler or patch is ideal for non-commercial asphalt repair jobs. A cold filler, such as our cold asphalt patch, offers several advantages over hot asphalt filler.

Virtually anyone can use cold patch. This is ideal for homeowners who prefer to DIY.

Hot asphalt filler, on the other hand, has to be handled carefully since it is applied at very high temperatures. Unlike the cold patch fillers, only professionals trained in road or asphalt repair have experience in handling the filler.

Note: If it is your first time tackling this type of asphalt repair job, then we recommend practicing applying cold filler first before you level up to hot asphalt filler.

If you use hot filler, you will also have to buy equipment that will melt the filler and apply it evenly on the asphalt surface you are repairing.

Unfortunately, you'll need to learn how to use the equipment to repair the asphalt with it. These equipment are also quite pricey for some people, making them impractical for non-commercial use.

Unlike hot asphalt fillers, cold patch fillers do not require additional equipment. Unless you have a lot of neighbors or belong to a neighborhood association that will enable you to split the cost to repair asphalt, the cost of this equipment isn't justified, as it will only be used once a year or every few years.

The asphalt patch is the simple answer for how to fix a pothole, but there is so much more you need to know before moving forward with your asphalt repair.

Cold versus hot asphalt patch is always the next question, and that leads to a key question: repair the pothole yourself or hire a pro? Let's remove the mystery of repairing holes on your pavement and take a look at exactly what you need to know.

Common wisdom says that hot asphalt is a better and longer-lasting repair for asphalt. That belief is a bit old-fashioned and ignores how good the modern cold driveway patch has become.

Here's the way you should really look at this question: are you willing to pay a pro to apply hot asphalt?

Frankly, the average DIYer does not have the equipment to keep this type of driveway repair hot. In addition, working with hot asphalt can be dangerous. A cold asphalt patch is the next best thing to use to repair an asphalt driveway.

While you're thinking about it, ask yourself this: how big of a repair is this?

Calling in a pro just to fix a three-inch-wide pothole may not be cost-effective. However, if you've got a large section of damage, compromises to the grade of the driveway (either in bulges or in depression), or multiple potholes, it may be worth your while to call in the professionals.

The first step to knowing how to repair asphalt is to analyze the area and get your supplies together. This way, when it comes time to patch potholes, you have everything you need to complete the job

Thanks to new modern formulas for cold asphalt patch, you can fill a pothole in any temperature and weather. This is a real positive: you can fix the hole before it gets worse (and it will!).

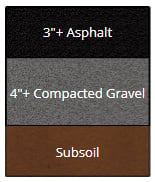

All types of pavement are poured onto a foundation of compacted gravel that’s at least four inches deep. This gives support to the actual blacktop surface.

All types of pavement are poured onto a foundation of compacted gravel that’s at least four inches deep. This gives support to the actual blacktop surface.

Any time you need to tackle asphalt repair, you need to repair any damage to the foundation. Plus, this will save on how much cold patch you use.

Take a look and see how much coarse gravel and sand you need to replace what’s been lost. It can't be stressed enough how important this part is when it comes to patching asphalt.

To fill a pothole with a long-lasting repair, it’s best if you square the edges of the hole.

To calculate how much cold patch you will need, take the longest part by the widest and multiply. You should assume leaving an inch of depth after topping up the foundation.

So, a two-feet-by-two-feet hole will end up being four square feet, and you’ll need one 50-pound bag of cold patch.

Remember: It’s always better to have too much cold patch for your asphalt repair than not enough!

Patch asphalt requires you to have certain tools and supplies at hand. You can’t stop partway through pothole patching to run out and get what you need, so make sure you’re all set to go.

Have you ever wondered how often pothole patching on roads fails, so maybe it's entirely possible that you can do better?

The opposite is true. Road crews don’t have the time to do the job properly: they get in, fill, and get out.

On the other hand, you have the time to fill a pothole the right way, so it’s long-lasting and professional.

Once you have all the supplies at hand, everything will go very smoothly with your asphalt repair. Here are four steps on how to patch asphalt.

The asphalt around a pothole is usually cracked and about to make the hole even bigger, so you need to remove the damaged pavement with an asphalt saw or a hammer and chisel (note: long screwdrivers make great chisels).

Also, repaired asphalt lasts the longest when you fill a square or rectangle instead of a round or oval hole, so make the edges of the pothole straight up and down. This is where an asphalt saw makes easy work of the job.

Part of knowing how to patch asphalt is to thoroughly clean out the area. This includes any and all plant life. If the roots don’t come out cleanly, pour in some vinegar to completely kill the plant and make sure it doesn’t grow through the patch.

Remove any and all debris, including the chunks of asphalt you just cut or chiseled out. Go as far down as you need to so you have an absolutely solid base. A stiff broom will help get debris out.

Before pothole patching, you must restore the foundation. Top up the hole with a coarse gravel and sand mix until it is only an inch deep.

You can also use any loose asphalt that you chiseled out of the pothole.

Tamp and compress firmly as you fill. To fill a pothole professionally, the fill must have a solid base to sit on.

For most residential pothole patching concerns, cold asphalt filler is the best material to use. Cold asphalt mix is cheaper, easier to apply, and does not require specialized equipment and skills that are necessary when working with hot asphalt.

Add a half to a full inch of driveway patch product—we recommend the Asphalt Kingdom Cold Patch—and tamp down before adding another layer. This eliminates troublesome air spaces. The last layer should slightly overfill the pothole.

Here is where the vibrating plate helps for the finishing of the asphalt repair. A lawn roller or metal tamper will work just fine if you don't have a vibrating plate.

Another option is you can lay a piece of plywood over the repair and drive over it. Oil the bottom side of the plywood to prevent sticking.

To fill a pothole professionally, you must make it level with the surrounding pavement. If after tamping down the cold patch, it is still not filling the hole, add some more and tamp again. Work quickly—this stuff sets quickly and dries hard.

Anyone can repair asphalt, but there are still two steps left for knowing how to patch asphalt so it will last.

All too often, property managers and homeowners skip this crucial step, and it sure doesn’t take long for the hole to reappear.

All too often, property managers and homeowners skip this crucial step, and it sure doesn’t take long for the hole to reappear.

Cold patch, just like all asphalt, is not sealed when installed. Unsealed, the patch will be exposed to the elements and become dry and brittle.

After four hours, the patch has cured and can be sealed. However, sealcoating does need proper weather conditions; you’ll need 50ºF temperatures and dry weather.

Winter Asphalt Maintenance

If you need to repair asphalt in the winter, wait until the spring weather is warm and dry. Brush or roll on a thin coat of seal coat, and allow it to dry completely. Repeat with a second coat.

Homeowners can obviously skip this finishing step for how to fill a pothole (unless you’ve painted a basketball court on your driveway!).

Homeowners can obviously skip this finishing step for how to fill a pothole (unless you’ve painted a basketball court on your driveway!).

Property managers need to finish their parking lot by painting any missing parts of the line striping.

Just as with sealcoating, the weather must be warm and dry. If the asphalt repair has been done where a line or other marking is, you must paint the area, too.

No need to pull out the line striping machine: use straight edges of cardboard or the correct stencil and an aerosol can of traffic paint to touch up the line markings.

This free asphalt driveways course is everything a property owner needs to know about asphalt maintenance and repair.

Knowing how to patch asphalt isn’t complicated, and you can fill a pothole any time of year.

Doing the work right away, rather than waiting until you have enough damage to make it worth a contractor’s time, will add years to the life of your asphalt.

Plus, the know-how lets you get the job done at a time best suited for you and your parking area.

Analyze the damage, and get your equipment and supplies together. Make sure you have enough gravel sand mix to replenish the foundation.

Order enough cold patch to complete the asphalt repair. Having everything near to hand is the most important step in how to patch asphalt. To fill a pothole professionally, remember these steps:

Road crews never have the time to cut edges or sealcoat. That’s why when they fill a pothole, it usually comes back. You know how to patch asphalt the right way, so wait no longer—get out there and start measuring your potholes

Surface patching is the most popular residential patching. In surface patching, an asphalt glue is added to the patch area, and hot asphalt is applied directly on top of the preexisting asphalt surface.

Surface patching is the most popular residential patching. In surface patching, an asphalt glue is added to the patch area, and hot asphalt is applied directly on top of the preexisting asphalt surface.

Surface patching is more inexpensive to do compared to cutting out and conducting asphalt resurfacing.

Infrared patching utilizes an infrared heating machine to heat up the existing asphalt in the pothole or asphalt seam. If the pothole or depression has lost too much asphalt, you may need to get asphalt scraps or recycled asphalt to fill in the gaps.

If your asphalt is still black in color, it still has the tar and bitumen that makes it flexible. If the asphalt is gray, you will need to get an asphalt rejuvenator to restore some of that flexibility.

Asphalt removal and patching is a good choice for property owners. It is permanent, but be forewarned that it is a more costly way of repairing damaged asphalt.

It isn't always necessary unless the problem is due to base failure (asphalt foundation). But if you're dealing with base failure, then you have to remove the asphalt completely. This is done before you can properly compact and prepare the base. This kind of patching is used often in high traffic zones.

All edges of the repair area should be cleaned for best tacking results. Try to make the edges straight and even. You can now compact and level the asphalt when the damaged area has been removed.

The new fresh asphalt patch is then applied in two layers, both about one and a half inches thick, compacting each layer for a more stable, permanent patch.

We recommend that an asphalt specialist provide this service for residential homeowners if you are intending to repair with hot asphalt.

Hot asphalt patching can be dangerous for homeowners, with material that is extremely hot. It also takes some skill to work the hot asphalt with a rake.

The asphalt needs to be leveled and has to be the right thickness. Asphalt repair contractors usually carry hot asphalt in an asphalt hot box. An asphalt hot box is insulated and heated to keep the asphalt mix hot.

This allows contractors and property owners to work with the asphalt in its workable form. Without an asphalt hot box, the asphalt would cool too quickly and turn to a solid form.

Hot asphalt is a long-lasting, durable product, made from rock, sand, tar, and bitumen. It is extremely hot when it is first applied so that it can be worked into the repair area.

As the hot asphalt cools, it hardens and becomes solid. It takes approximately 24 hours for a hot asphalt patch to harden and be safe to drive on.

Anyone can use cold patch, and the new Asphalt Kingdom Rapid Set Cold Asphalt Patch is even easier than most products on the market today.

The good news is cold asphalt patch can be applied in all weather conditions as it adheres to wet and dry surfaces. Remove any loose material from the pothole, and fill it with cold asphalt patch using a shovel.

The pothole can then be compacted with a shovel, hand tamper, vibratory tamper, or truck tires. Regardless of the compaction method, the patched area can be immediately opened to vehicular traffic, as it will not kick up, push, or ravel.

Prolonging the service life of your driveway doesn't just depend on using the best materials during its construction. Conducting asphalt repair as quickly as possible is also important.

Over time, normal wear and tear will naturally result in the formation of cracks and holes in your asphalt. These are easily repaired.

Not knowing how to repair potholes or waiting for good weather are the common excuses made by most people.

A product called asphalt cold patching has made it possible to set aside those excuses. It can be used on wet or dry surfaces. This material will fill up all spaces in the pothole and displace the water.

Asphalt cold patching has made the whole process of repairing potholes and wide cracks on the road so uncomplicated that virtually anyone can do it.

Unlike the conventional way of repairing asphalt on a damaged driveway, where the hot asphalt material requires specialized equipment and expertise, with a cold patch you don't even need to be an avid DIY person.

All you need is the repair material and some simple tools that you likely already have in your garage. Finally, you need to follow simple instructions.

With the asphalt cold patch method of repairing wide cracks and potholes on your driveway, you don't have to wait for the perfect weather either.

There is no better time to repair any damaged asphalt on your driveway than the present. Not attending to cracks and potholes right away will increase the risk of expanding the damage on your driveway.

Cold patch is made up of different asphalt polymers. They are durable and versatile enough that they can be used in any weather condition.

You can apply it right after it has rained, as the asphalt cold patch formulation makes it possible to be poured even in potholes that are filled with water.

The pothole or wide crack should, however, be free of dirt, soil, rocks, plant material, and other loose debris.

The cold asphalt material is made up of polymer-modified asphalt that is basically hot asphalt that has been cooled.

Cold patch is pliable in the container, making it easy to pour and spread out. It is also quick-acting, as it dries quickly and becomes rock-hard in as fast as three hours.

You no longer have to wait for good weather to repair asphalt.

People working with cold patch can expect the same performance as hot mix asphalt when it comes to durability.

People working with cold patch can expect the same performance as hot mix asphalt when it comes to durability.

Cold mix asphalt will blend with the pavement or driveway. It can even prevent cracking of the areas surrounding the potholes.

During compaction, cold mix asphalt will remove all the liquid out of the hole, which allows users to make repairs immediately, regardless of weather.

Using cold patch for asphalt repairs also eliminates some tedious steps in the process. This translates to greater savings not just in cost but also in the amount of time spent doing the repairs.

With the cold asphalt filler, the steps involved in blacktop pothole repair are reduced to basically three stages: cleaning, applying the cold mix asphalt, and compacting or tamping.

Using a tack coat prior to applying the asphalt mix is also not necessary anymore. All you really need to repair an asphalt pothole is the cold asphalt filler.

Other benefits include less waste produced during the repair process and no health concerns with regard to the inhalation of fumes, which is usually the case with hot asphalt mix.

Indeed, it is not just easy but also cost-effective for homeowners when they use cold mix asphalt to have the repairs on their blacktop driveways completely under their control.

In addition to asphalt, the cold patch fillers, particularly the cold asphalt patch, can also be used on concrete, steel, wood, and other hard surfaces.

Thinking about asphalt welding? You can earn $5 to $7 per linear foot with this job. As a sealcoating contractor, you will come across driveways and parking lots that have patches or ridges that are a bit of an eye-sore.

You may also see residential driveways that have been affected when the city came through and repaved the roads.

Asphalt welding is a repair process that involves taking a propane-powered tiger torch and heating the patch seam (around the edges) for about three to four linear feet along the seam and then reworking the asphalt with an asphalt rake and blending the edges of the patch seam into the main body of the surface.

Once you have spread the asphalt around on the edge to make it uniform, you can use a steel hand tamper or a vibrating plate to tamp the asphalt back down to a solid form.

It's important that you don't burn the asphalt during this process. Avoid having a direct flame touching the asphalt at any time, as this will burn the tar and bitumen out of the asphalt, leaving it fragile and exposed to cracking.

You will know that you're burning the asphalt if it starts turning a grayish-white color. The goal is to heat the asphalt to a blackish-oily color so it can be worked with a rake and then tamped.

You can set yourself up for this service for under $1500, and we carry all the equipment that you'll need to get this job done right.

Call one of our specialists about asphalt welding and get advice on the best tools and equipment to get set up. We will also be happy to train you via telephone so that you can start earning on your first asphalt repair job.

Take a look at our vibrating plate to help make tamping asphalt or concrete pothole filler a breeze.

You can also take a look at our Mini Infrared Asphalt Heater or the AK4000 Hot Asphalt Box.

Asphalt surfaces should be sealed with commercial-grade asphalt emulsion sealer to prevent asphalt patching and decay.

The tools you need for sealcoating are simple and easily acquired. You will need something to stir the seal coat material with and a squeegee or floor broom to apply it.

Before applying the sealcoat, which is preferably done a couple of days after the repair to allow the asphalt filler to cure, you have to clean the area first with a broom or a high-pressure sprayer.

With user-friendly products like the cold asphalt patch, it is now easy for property owners to repair their asphalt surfaces. While this product is durable and is guaranteed to last long, it is still best to apply sealcoating to finish the repair.

Applying sealer will make the asphalt patch flexible. Without sealcoating, asphalt surfaces will oxidize, crack, and crumble. Sealing it provides full protection to every square foot of the asphalt.

It can also extend the lifespan of your asphalt driveway patch. This is important, especially since asphalt is exposed to the sun and moisture every day.

Apart from extending the lifespan of your driveway, you will also save money in the long run. Maintaining the condition of an asphalt driveway is very important.

Sealcoat after your asphalt repairs to make your parking lot or driveway last longer!

Indeed, improper or lack of maintenance can speed up the deterioration of the asphalt. Plus, you'll need to have it repaved sooner than you were planning to.

Asphalt repair using cold asphalt patch is a simple process and a lot cheaper than repaving altogether. Replacing asphalt also requires professional help, and it can be expensive.

Aside from the savings from sealcoating your asphalt driveway patch, the bigger picture here would be that you will maintain or even increase the value of your property if you plan to sell in the future, especially since the asphalt driveway is one of the first things that buyers see.

Ideally, sealcoating is done a year after the asphalt has been installed and every two to four years after that for maintenance.

If parts of the asphalt surface start to appear lighter or have white patches even before that time span, this is an indication that the surface already needs to be sealcoated.

In the case of an asphalt driveway patch usually applied to repair potholes, wait 24 to 48 hours for the patch to cure before applying the sealcoat.

There is no excuse for not doing this maintenance procedure for your asphalt driveways. You just need to invest in the right tools and know the proper steps.

Usually, sealcoating an entire driveway or lot requires a sealcoating sprayer for easier and faster application. The sprayer also has the added advantage of being able to apply an even layer of sealer.

If you need to sealcoat just a small-sized asphalt driveway patch after repairing a pothole, you can do so by hand using a squeegee.

There are several things to keep in mind when sealcoating:

Watch more of our videos in our Video Center

Asphalt patching is a great business opportunity for asphalt contractors looking for an additional income stream.

Homeowners, business owners, and countries spend millions of dollars every year to repair asphalt cracks and repair potholes. It is more cost-effective to repair asphalt surfaces rather than re-paving.

The same goes for driveways. It is much more cost effective to patch compared to replacing your whole driveway.

Free Guide: 5 Ways to Ruin Your Asphalt

Free Guide: 5 Ways to Ruin Your Asphalt

Pavement maintenance is critical to the value of your property. Don't let these five mistakes ruin your asphalt and cost you hundreds or thousands of dollars - get our free guide now!

Get Your FREE Guide Now!

Stop small pavement problems from turning into big callbacks. See the asphalt services that matter ...

.png?width=360&height=202&name=Blog%20Images%20(5).png)

Is your parking lot failing? Learn how asphalt resurfacing saves money and restores safety without ...

Learn how to start asphalt crack fill services with a simple plan, proven tools, and profitable ...